Master core technologies and establish national brands

Cangzhou Qingfeng Car Body Mold Co., Ltd.

Cangzhou Qingfeng Car Body Mould Co., Ltd. was established on May 17, 2004 and is located in the North Development Zone of Fort, Nanxiakou Town, Dongguang County. It is an executive director unit of Guangdong Mould Industry Association and a group member unit of China Mould Industry Association. The factory covers a total area of 100000 square meters, including a construction area of 60000 square meters. The company has 200 employees, a registered capital of 53 million yuan and fixed assets of 60 million yuan. It is mainly engaged in automobile body panel mold products and coking and steelmaking complete sets of equipment products. The main production equipment includes 5 sets of 8T and 5T medium frequency induction steel shell electric furnaces and 80 sets of casting machinery and equipment, 18 sets of excellent automatic control, inspection and testing equipment such as Shimadzu emission spectrometer PDA--7000, and 150 sets of high-speed numerical control machining center, high-precision three-coordinate measuring instrument, large and medium-sized press debugging equipment and boring, turning, milling, grinding and other equipment.

In recent years, the company has always adhered to scientific and technological innovation as the forerunner, increased investment and development of scientific and technological innovation, through the unremitting efforts of the company's technical research and development personnel, now has self-developed dry sand negative pressure lost foam casting extrusion vibration molding method, large casting sand box, encrypted pumping bar and other ten national patents. Our company uses the advanced "lost foam, dry sand, and negative pressure casting technology (referred to as V-EPC) in the domestic foundry industry. The annual design production capacity is nearly 50000 tons. The appearance and internal quality of the products have reached the national standards. The products are sold in Shanghai, Beijing, Tianjin, Chongqing, Hebei, Jiangsu, Shandong, Guangzhou, Liaoning, Anhui and other vast areas, mainly for FAW-Volkswagen, Shenyang Jinbei, Chery Hu, Jianghuai, Zhengzhou Yutong, SAIC Baojun, BAIC New Energy, Tesla, Mercedes-Benz, Baoding Great Wall, Jiangxi Hanteng and other major automobile OEMs and new energy automobile companies to produce supporting automobile mold products, well received by users.

In March 2019, the company reached the acceptance standard of air pollutant emission for green casting enterprises in accordance with the Implementation Plan for Rectification and Promotion of Dongguang County Foundry Industry. The company contacted professional dust removal engineers to carry out a comprehensive upgrade and transformation of each process. The company invested 10.6 million yuan in rectification funds to redesign and install the environmental protection dust removal equipment for smelting, pouring, modeling, cleaning and polishing processes, and replaced the original high-energy-consumption aluminum shell electric furnace with a magnetic yoke steel shell medium-frequency electric furnace, the sand treatment line and the sand drop process are closed from the new design for dust removal and effective dust collection.

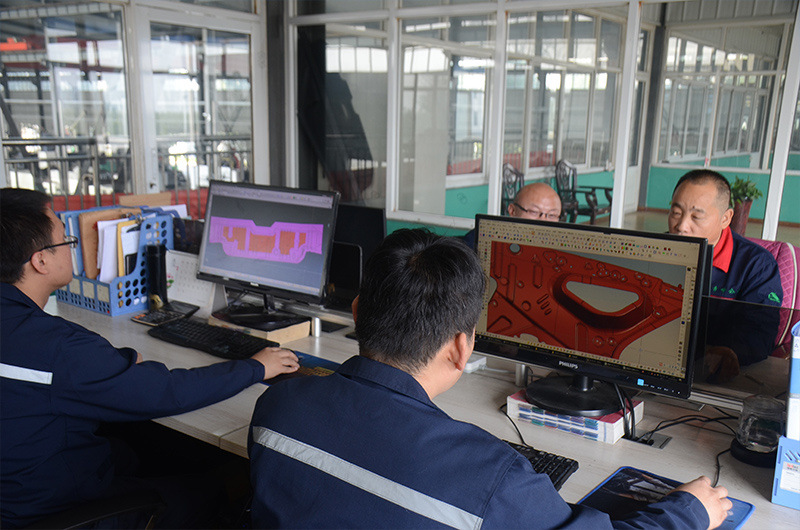

Qingfeng Real Scene

Independent closed grinding rooms are installed in the casting cleaning area, and each grinding room is combined into a high-power dust collector for dust removal by top suction. The company has set up a physical and chemical room equipped with a direct reading spectrum analyzer Shimadzu-PDA5500A to carry out pre-furnace inspection and strictly control the quality. In addition, the renovation of 13000 square meters of old factory buildings and the hardening of workshop roads in the factory area have been carried out. The construction process has been strictly in accordance with the standard requirements of the nine modernizations, and the rectification effect has been maintained for a long time, and the environmental protection work has been adhered.

The company uses self-developed casting processes and tooling equipment to completely improve the current situation of backward technology and equipment and environmental pollution in my country's industrial cluster casting industry, greatly improve the intrinsic and surface quality of products, and achieve a truly green, environmentally friendly, A modern foundry industry with Chinese characteristics that reduces staff, increases efficiency, saves energy and reduces consumption, realizes the upgrading and transformation of the foundry industry, promotes the healthy and sustainable development of the foundry industry, and comprehensively increases the technical added value of foundry products.

Qingfeng people will continue to forge ahead and make unremitting efforts to further promote the development of the mold industry and better meet customer needs!